All your carbon shall be methanol

First Posted: 2023.10.03, Last Revised: 2023.10.03, Author: Tom Brown

All your carbon shall be methanol

Arguments for mopping up all carbon in wastes and residues into methanol; use it to supply sectors that can't be electrified

TL,DR: methanol is liquid; easier to transport/store than CH4/H2/CO2; costs scale down nicely to multi-MW size

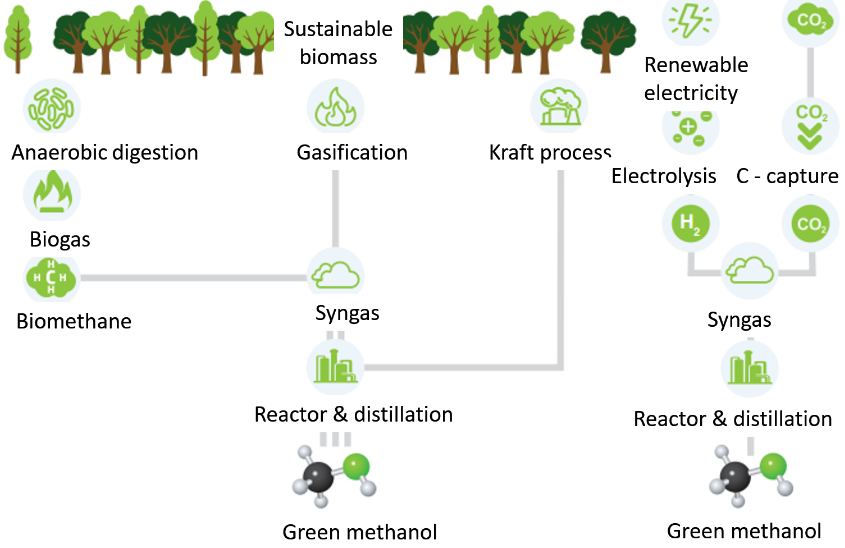

Figure 1: Methanol production routes.

—

We need carbonaceous fuels for big chunks of shipping, aviation and chemicals

Methanol can serve all of these

Flexible, distributed synthesis from wastes and residues (topped up with green H2, "bio-e-methanol")

=> minimise direct air capture, and transport of fiddly gases

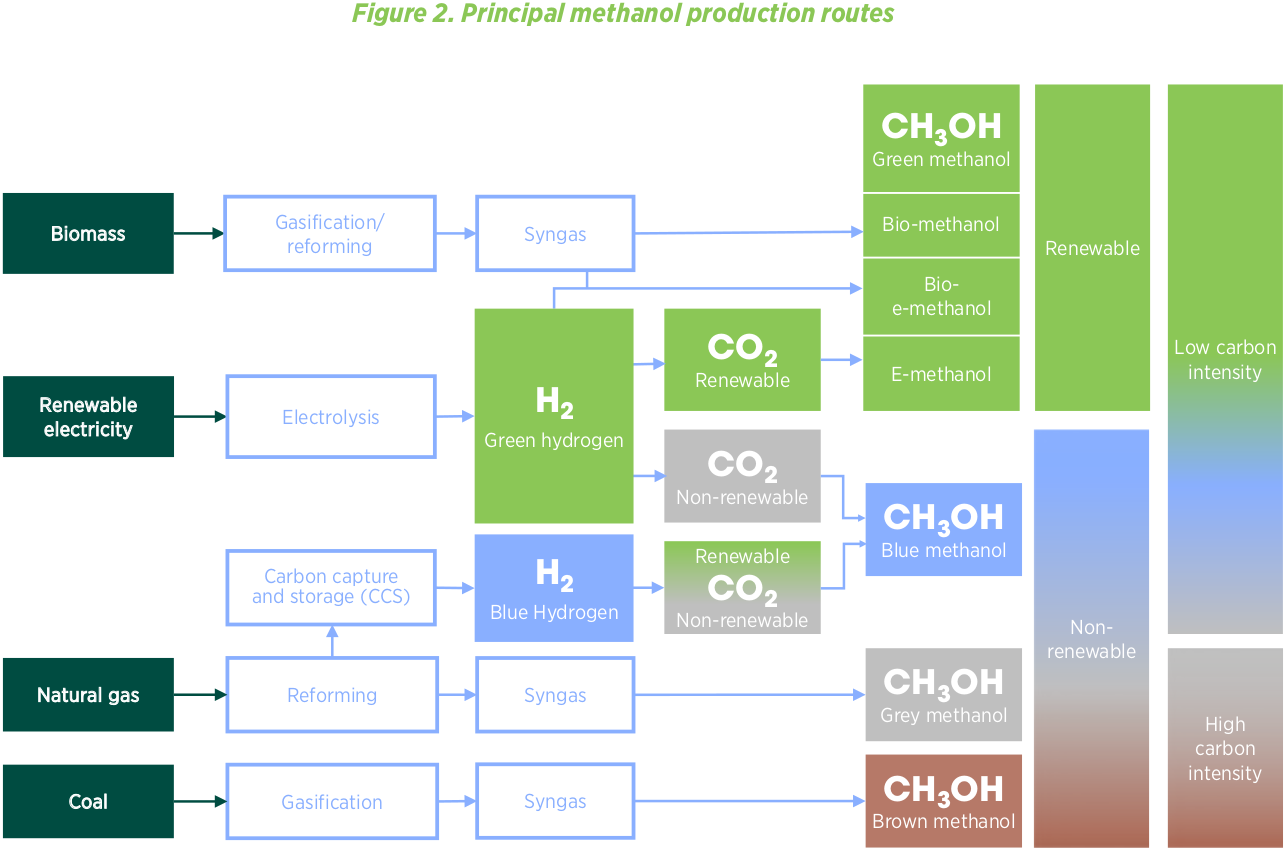

Figure 2: Methanl production routes

—

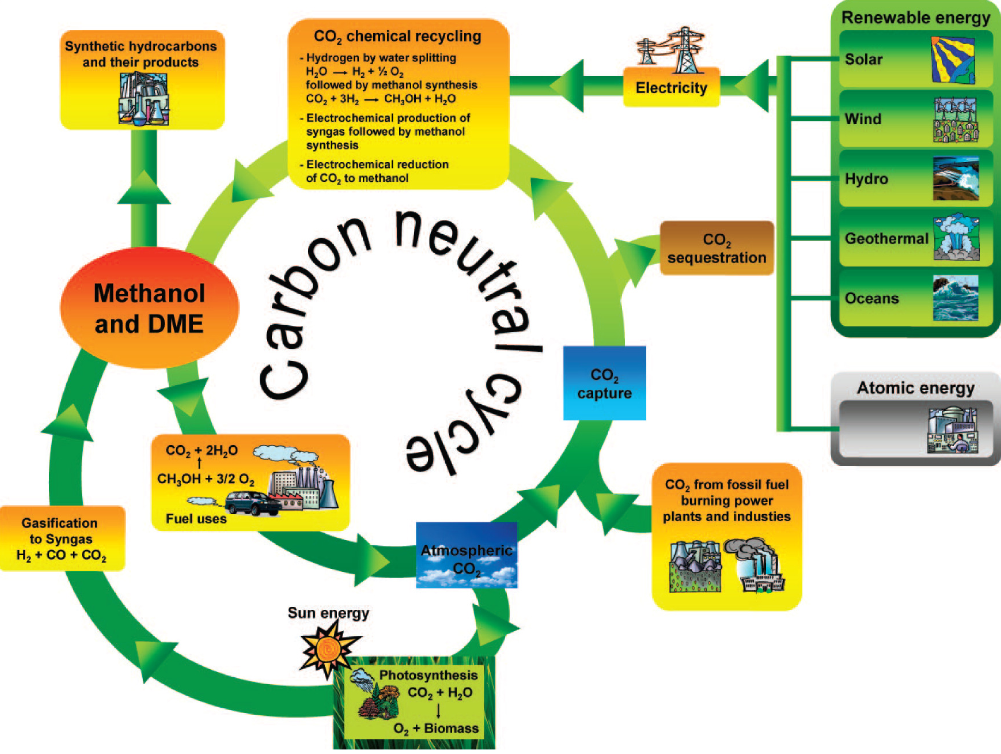

None of these ideas are new; ideas of a methanol economy have been circulating since the 1980s (Asinger, Olah, etc.).

Novelty is to put them in updated net-zero context, remove daft bits like coal-to-methanol and methanol for land transport.

https://en.wikipedia.org/wiki/Methanol_economy

Figure 3: Methanol economy

—

ok, now for the basics

methanol, MeOH, CH3OH, is a liquid up to 65 C

liquid => store in tanks, transport by vehicle/pipeline

burns more cleanly than other fuels (no soot or SOx, low NOx)

synthesised from CO, CO2 and H2 (already at megaton scale in China)

don't drink it!

Figure 4: Flames of different fuels

—

in cost-effective net-zero scenarios almost everything gets electrified

but some thorny sectors remain: dense fuels for long-distance shipping and aviation; feedstocks for chemicals

Maersk sailed a container ship with green methanol, has ordered lots

https://www.maersk.com/news/articles/2023/06/26/maersk-orders-six-methanol-powered-vessels

—

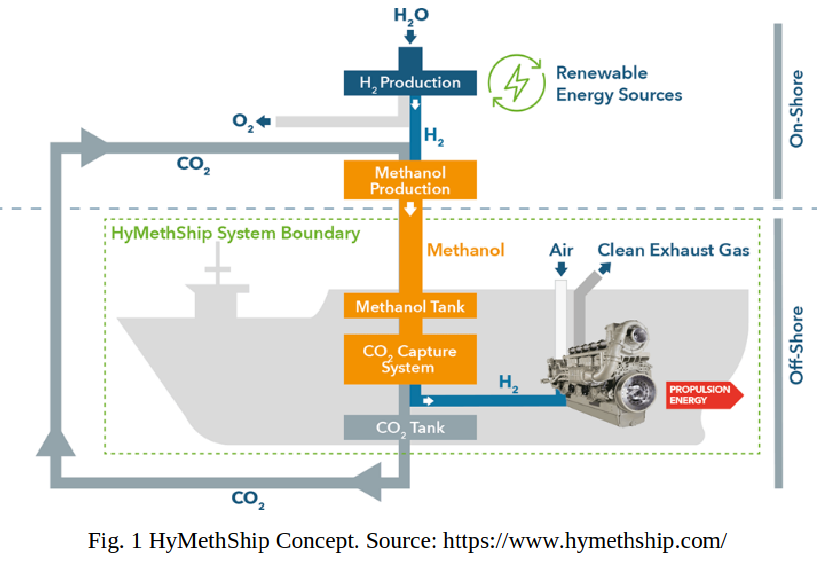

There are even funky concepts around to capture the CO2 on board the ship (using a reformer - the hydrogen goes to a fuel cell) and bring it back to land for synthesis

Figure 5: Ship with carbon capture

—

while most studies consider Fischer-Tropsch for kerosene, methanol is also in the running!

methanol-to-kerosene is around 90% efficient, but not yet commercial

going via methanol has big benefit that methanol synthesis can be run more flexibly than FT (big advantage with VRE!)

—

even if we reduce, reuse, recycle, we still need some primary production of plastics, paints, adhesives etc.

methanol can serve as a flexible basis for many of these (many already used in China)

obvs we still will also need ammonia for fertilisers, etc.

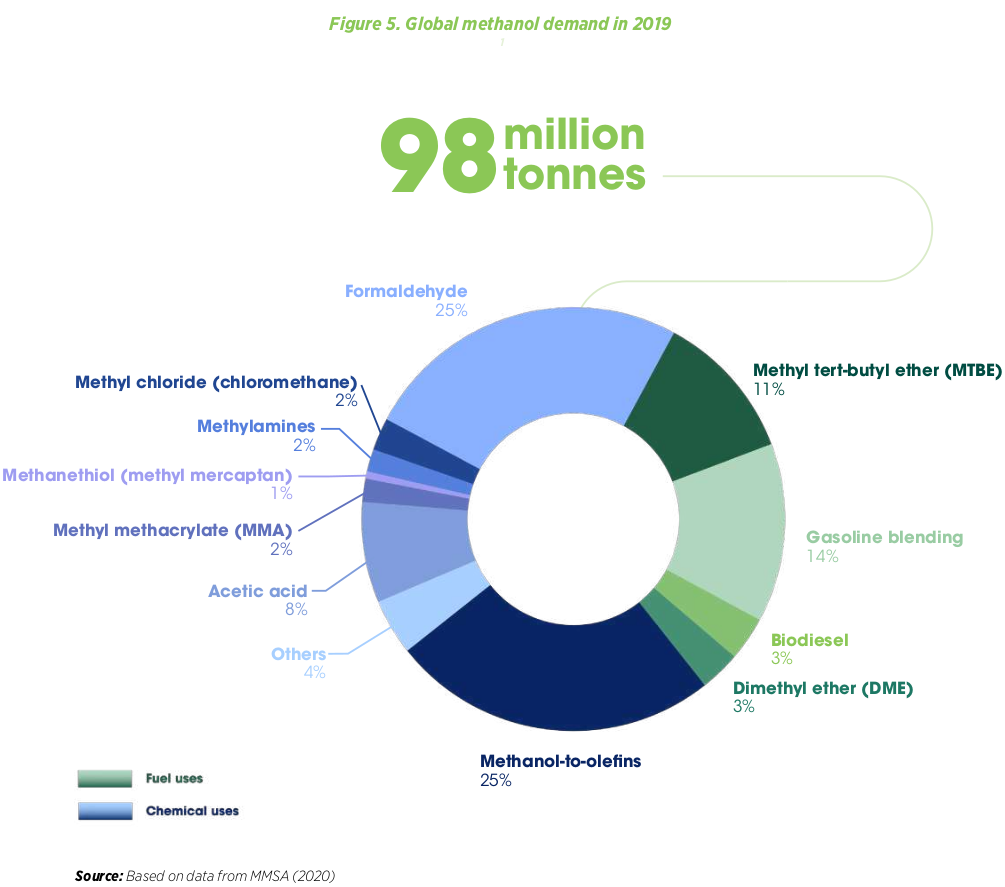

methanol use today:

Figure 6: Methanol usage in chemical industry

—

Yes, the synthesis of methanol adds losses to chain of conversion, but you also save e.g. the compression losses of transporting and storing gases like hydrogen.

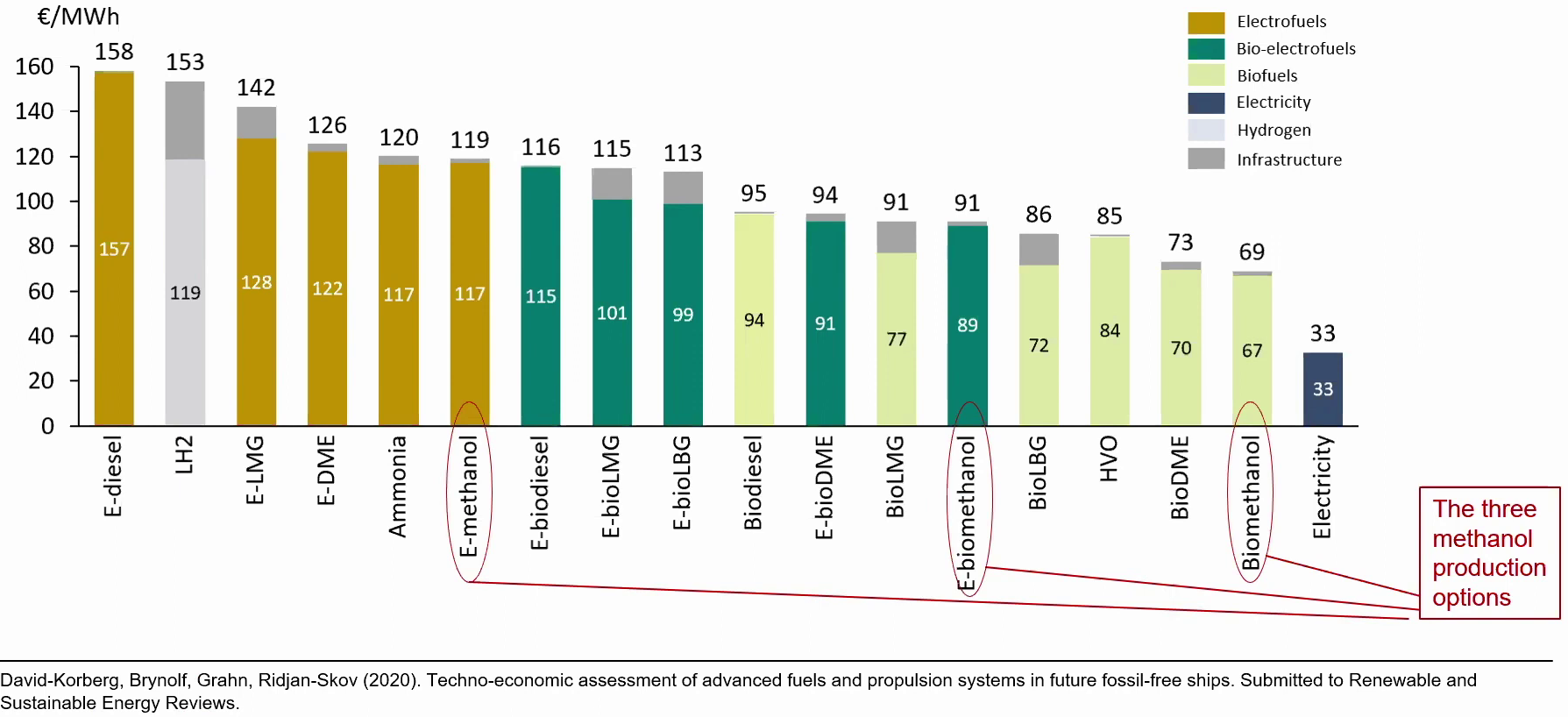

If carbon comes from sustainable biogenic sources, cost can be 70-90 EUR/MWh

https://doi.org/10.1016/j.rser.2021.110861

Figure 7: Methanol production costs.

—

So what does methanol production look like?

Let's look first at the gasification route, suitable for solid wastes and residues.

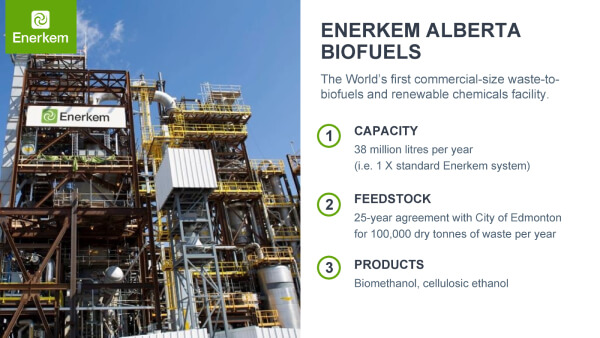

Enerkem's plant in Canada uses non-recyclable and non-compostable waste, thus reducing landfill, to produce up to 38 million litres per year

Figure 8: Enerkem plant in Alberta, Canada.

—

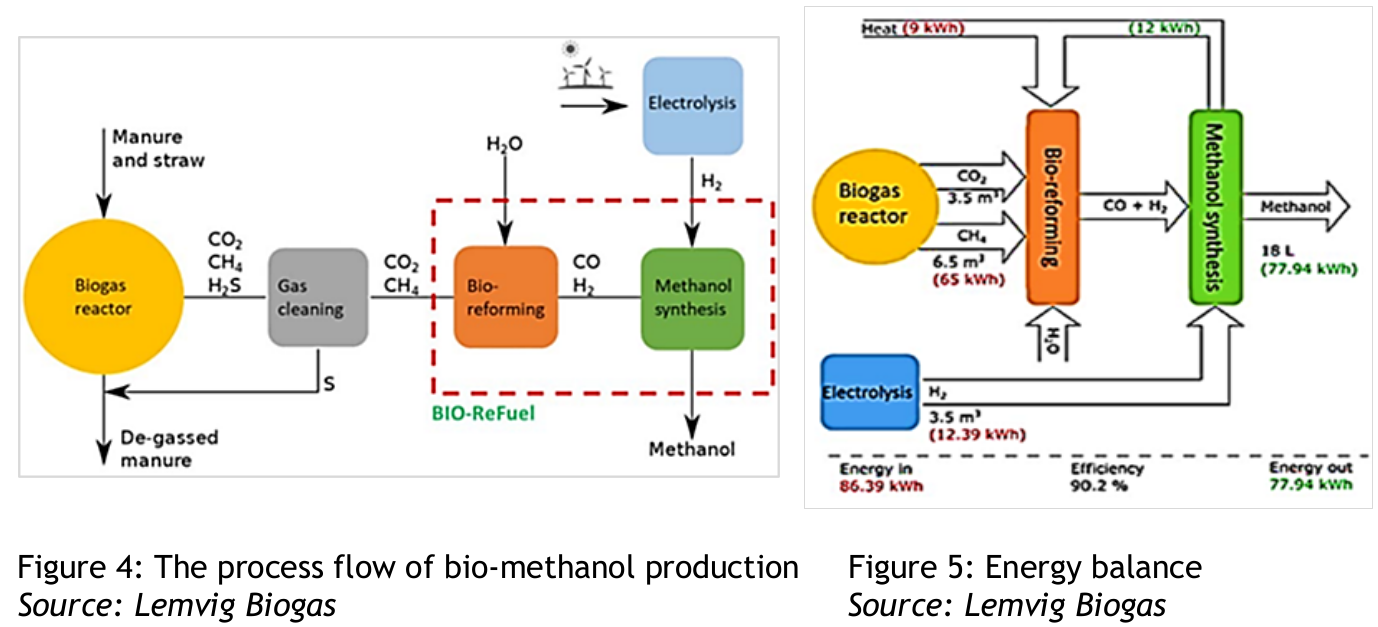

In Denmark several projects are currently underway (BioReFuel and eSMR-MeOH) using biogas, adding electrolytic hydrogen to soak up the excess carbon, to produce e-biomethanol.

https://www.ieabioenergy.com/wp-content/uploads/2020/12/Case-Story-DK_-Green-Methanol_web-1.pdf

Figure 9: Methanol production from biogas

—

M2X Energy is building small modular reactors 😂 to convert fossil flare gas to methanol

Again note scaleability of methanol, and transportability - lack of easy transport of methane is why it's flared in 1st place

Methanol is the distributed solution!

Figure 10: M2X small-scale methanol production

—

The M2X energy synthesis units produce at a rate of around 1 MW - this would be bigger than most biogas facilities, at least in Germany, so either the substrate or the biogas itself would have to be pooled into each methanol synthesis facility.

—

Do CO2 demand and supply match?

In our EU model, there is ~400 MtCO2/a from wastes and residues (manure, MSW, straw, forestry residues, etc.).

Demand for aviation fuels is ~135 MtCO2/a, shipping ~150 MtCO2/a and chemicals ~80 MtCO2/a.

So enough in principle to avoid DAC.

—

Green H2 is still needed to mix with excess carbon in biomass, for ammonia and steel, but transport could be minimised.

Methanol could be used as a hydrogen carrier for e.g. backup power.

Or as a carbon carrier to get e.g. cement emissions from inland sites to coast for CCS.

—

To summarise:

Electrify everything*

\*Use methanol for the rest**

**OK, also a bit of hydrogen for ammonia and steel

Happy to hear comments or thoughts!

—

PS For further reading I recommend the excellent report by IRENA and the Methanol Institute

https://www.irena.org/publications/2021/Jan/Innovation-Outlook-Renewable-Methanol